Tel: 0086-17121115666

Email: sales@wiremeshfence.com

Welded bar grating, a versatile and durable product by BMP, has become a staple in industrial and commercial construction due to its robust design and versatile applications. It offers high strength, optimal water drainage, and exceptional anti-rust performance.

Strength and Durability: Welded bar grating can support heavy loads and withstand harsh conditions.

Open Design: Its open grid pattern allows for the easy passage of light, air, and water.

Low Maintenance: Once installed, it requires little upkeep to maintain its functionality.

Versatility: Available in various sizes, materials, and finishes to meet different needs.

Slip Resistance: The surface offers a natural grip, reducing slip hazards.

Safety: The slip-resistant feature enhances safety by minimizing the risk of slips and falls.

Cost-Effective: It is an affordable solution for many industrial and architectural applications.

Easy to Install: Lightweight and easy to handle, making the installation process quick and straightforward.

Durability: Its robust construction ensures a long service life, even in demanding environments.

Improved Ventilation and Lighting: Its open design allows for better air flow and natural light distribution.

Industrial Flooring: Commonly used in factories and plants for safe and durable flooring.

Walkways and Platforms: Ideal for creating safe, stable walkways and platforms in various settings.

Drainage Covers: Perfect for use as covers for drainage systems, allowing water to pass while providing solid ground.

Stair Treads: Provides a strong, slip-resistant surface for stairs in industrial and commercial buildings.

Fencing and Partitions: Can be used to create secure and see-through fences and partitions.

Welded bar grating offers a practical solution for many design and safety challenges, making it a popular choice in a wide range of industries.

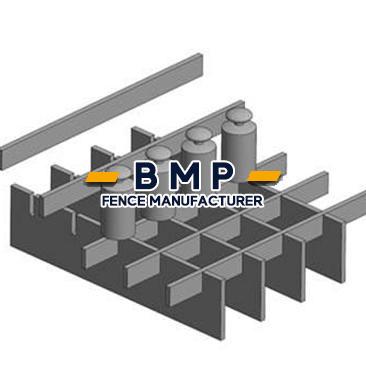

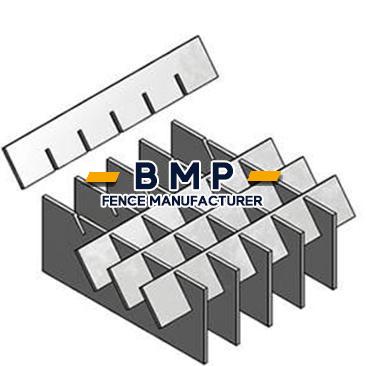

same height. |  Bearing bars are higher than the cross bars,bearing bars are notched. |

higher than the cross |  Notch on the bearing bars are at a angle of 30° or 45° |

Welded bar grating is constructed through a resistance-welding process that permanently joins the cross rods to the bearing bars. Our welded grating features a unique design with twisted square rods and rectangular bars or I-type bars, offering a strong and secure product. Its high lateral stiffness, facilitated by press-locking, allows it to be used in a variety of special applications.

Moreover, the grating's surface treatments include galvanizing, painting, and powder coating, ensuring corrosion resistance and a pleasing aesthetic. The serrated surface option enhances its non-slip performance, making it safe and secure for various environments.

Our welded bar grating is available in different materials such as low carbon steel and stainless steel, catering to various customer requirements. The bearing bars and cross bars can be notched and have the same height, creating an efficient, high-capacity platform.

Welded bar grating's attractive silver exterior coupled with simple lines reflects modern design trends, making it aesthetically pleasing without compromising functionality.

| Specification | Description |

|---|---|

| Material | Low carbon steel, Stainless steel |

| Surface Treatment | Galvanized, Painted, Powder coated |

| Surface Type | Smooth surface, Serrated surface |

| Serrated Surface Type | PR/S1, PR/S2, PR/S3 |

| Bearing Bar Dimensions | 25x3, 25x4, 30x3, 30x4, 30x5, 32x5, 40x5, 50x5, 75x10 mm |

| Bearing Bar Pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 34.3, 35, 40, 41, 60 mm |

| Cross Bar Pitch | 38, 50, 76, 100, 101.6 mm |

| Material Grade | Q235, A36, SS304 |

| Standard Compliance | YB/T 4001.1-2007, ANSI/NAAMM(MBG531-00), BS4592-1995, AS1657-1992 |

| Specification | Description |

|---|---|

| Material | Carbon steel, Stainless steel |

| Cross Bar Pitches | 24-200mm (50mm, 76mm and 100mm recommended) |

| Surface Process | Hot-dipped galvanized, Electro-galvanized |

| Appearance | Simple outline, Silver color |

| Water Draining | 83.3% leakage area |

| Antirust Performance | Excellent (hot-dip galvanizing) |

| Theft Prevention | Cover connected with frame by gemel |

Serrated welded steel grating serves a broad range of applications. It's widely used as platforms, stair treads, walkaways, and floors in industrial, civil, and commercial buildings. It provides high safety performance, does not accumulate rain, snow, or dust, and its installation and removal process is straightforward, contributing to a longer lifespan.

Our welded bar grating complies with multiple national standards, including YB/T 4001.1-2007 (China), ANSI/NAAMM(MBG531-00) (USA), BS4592-1995 (UK), and AS1657-1992 (Australia), to name a few. With a focus on quality and customer satisfaction, BMP ensures that its products meet the highest global standards.

BMP offers steel grating that goes through a hot-dip galvanizing process. You can choose from carbon steel or stainless steel. They use top-notch equipment to make these gratings. This method ensures welding the gratings well, achieving a smooth surface, and enhancing their strength.

The hot-dip galvanized steel grating features superior anti-acid and alkali corrosion resistance. It forms a stable protective film on the zinc surface, extending the product's lifespan and ensuring maintenance-free use. It also comes with an anti-theft design, providing a secure solution for various industrial and commercial settings.

BMP's welded bar grating is a high-performance, durable, and versatile solution for various industrial and commercial applications. Its features and benefits, including high strength, optimal water drainage, anti-corrosion properties, and compliance with international standards, make it a top choice for construction projects. Choose BMP's welded bar grating for a secure, durable, and high-quality solution.

Looking for affordable Perforated Stainless Stee

Explore the factors influencing garrison fencing

Discover the convenience of Temporary Chain Link

Contact: Frank

Phone: 0086-17121115666

Tel: 0086-318-7883678

Email: sales@wiremeshfence.com

Add: 053600 B125-B135 Ziwu Indutries Zone Zi Wen Town Anping County Hengshui Heibei Province China

We chat