Tel: 0086-17121115666

Email: sales@wiremeshfence.com

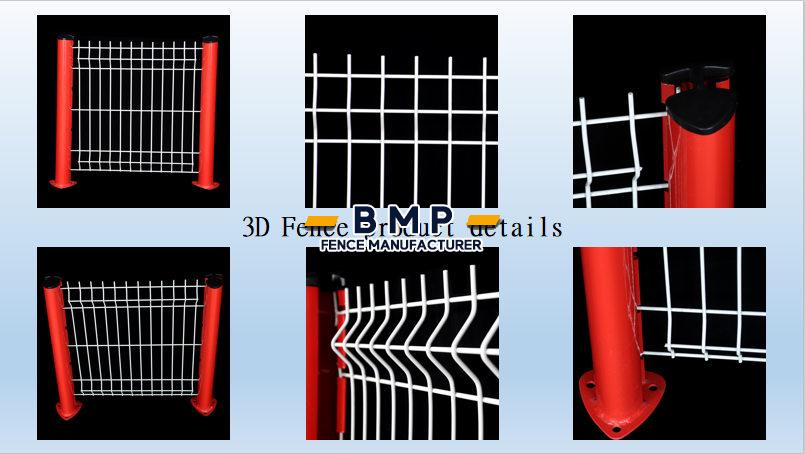

Wire Mesh Fence panels are often overlooked when considering ways to enhance security and aesthetic appeal for a property. Wire Mesh Fence Panels, in particular, offer an excellent solution, providing robustness and adaptability. Made from durable horizontal and vertical wires of 5mm or 4mm diameter, they offer immense strength, resistance, and stability. To further increase the strain capacity, these panels come fitted with horizontal molds.

Wire Mesh Fence Panels are finished in two versions. The basic version is galvanized, but segments can be varnished in colors as per the RAL color table. The wide selection of shades lets you customize the design of your fencing to match any individual requirement or the architectural needs of the construction.

| Specification | Detail |

|---|---|

| Panel height | 0.63m, 1.03m, 1.23m, 1.5m, 1.53m, 1.7m, 1.73m, 1.8m, 1.83m, 2.0m, 2.03m, 2.43m |

| Panel Length | 2.0m, 2.5m, 3.0m |

| Wire Diameter | Gal + PVC Painted: 3.85mm/4.0mm, 4.85mm/5.0mm; Gal + PVC Coated: 3.0mm/4.0mm, 4.0mm/5.0mm |

| Mesh Size | 50200mm, 55200mm, 50150mm, 55100mm |

| Folds No. | 2, 3, 4 |

| Colour | RAL6005 dark green, RAL9010 white, RAL5005 blue, etc. All RAL colours can be available |

| Post 1 (Rectangular) | 40x60mm (thickness: 1.2/1.5/1.8/2.0mm), 60x60mm (thickness: 1.5/1.8/2.0/2.5mm) |

| Post 2 (Peach) | 70*100mm (thickness: 1.2mm) |

| Post 3 (Round) | 60mm (thickness: 1.2/1.5/1.8/2.0mm), 48mm (thickness: 1.2/1.5mm) |

| Post Height | As per request |

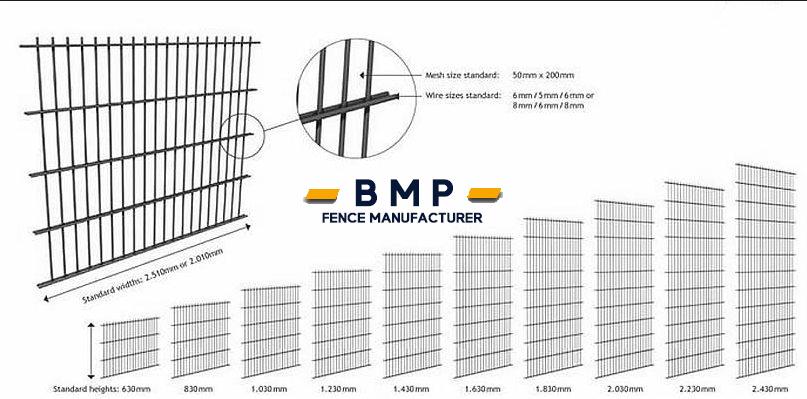

| Height x Width Panel (mm) | Mesh Size (mm) | Wire Diameter (mm) | Post Height (mm) |

|---|---|---|---|

| 630x2500 | 50x200 | 8x2+6 | 1100 |

| 830x2500 | 50x200 | 8x2+6 | 1300 |

| 1030x2500 | 50x200 | 8x2+6 | 1500 |

| 1230x2500 | 50x200 | 8x2+6 | 1700 |

| 1430x2500 | 50x200 | 8x2+6 | 1900 |

| 1630x2500 | 50x200 | 8x2+6 | 2100 |

| 1830x2500 | 50x200 | 8x2+6 | 2400 |

| 2030x2500 | 50x200 | 8x2+6 | 2600 |

| 2230x2500 | 50x200 | 8x2+6 | 2800 |

| 2430x2500 | 50x200 | 8x2+6 | 3000 |

Fence Panels Packaging:

place a rubber mat at the bottom of each pallet to prevent damage to the panels.

add four metal corners to each pallet to enhance its strength.

place a metal plate under the plastic bandage to lessen the pressure on the fence panels.

put a wooden plate on top of each fence panel to protect the panels from being crushed by other pallets.

Wire Mesh Fence Panels Post Packaging:

We already install the caps on top of each post. This saves you time and labor costs.

pack each post in a long plastic bag to protect it from friction damage.

pack all posts on a metal pallet for easy loading and unloading.

Welded Wire Mesh Fence Accessories Packaging:

We pack all accessories in a small plastic bag, and then we put them in a carton box. The size of the carton box is 300300400mm.

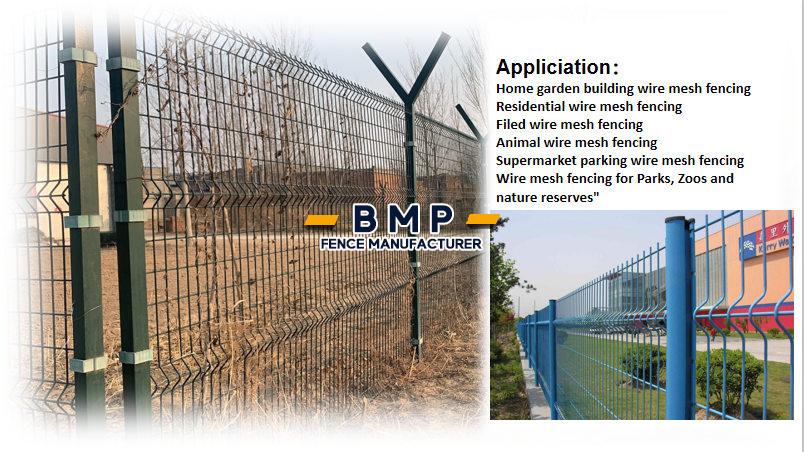

Wire Mesh Fence Panels are remarkably versatile and suitable for various applications. They are ideal for use in public buildings, private properties, residential perimeters, parks, zoos, and nature reserves. Besides the practicality and security, these panels are also appreciated for their visual appeal. The ability to customize color according to the RAL color table ensures that they blend seamlessly with any architectural style, enhancing the overall aesthetics of your property.

Vandal Resistant: The panels are highly resistant to damage, making them perfect for areas where vandalism could be an issue.

Low Maintenance: Once installed, these panels require very little maintenance, saving you time and resources.

Strong and Reliable Security: The robustness of the wire mesh makes it a formidable barrier, providing reliable security.

Attractive Appearance: Despite being a practical security measure, these panels do not compromise on aesthetics, making them an attractive addition to any property.

Process: We start with the raw material. We straighten and cut it, then weld it. Next, we create the folds. After that, we do a galvanizing process (it can be either hot-dipped or electro galvanized). Then we go through a parkerising process. We finally apply a PVC coat and pack it up for shipment.

Surface Treatment: We use two main methods of surface treatment.

In the first Wire Mesh Fence Panels method, we start with a black wire. After we weld it, we galvanize it. Finally, we add a PVC coat. This process helps protect the points where we welded the wire.

In the second method, we begin with a galvanized wire. We weld it and then go through the parkerising process. Finally, we apply a PVC coat. This method gives a basic level of protection against corrosion and it is a more cost-effective option.

For inquiries, samples, and order placements, feel free to reach out to our experienced staff. We offer a professional and fluent English service, customized design options, and exclusive solutions designed by our highly trained and professional engineers. With special discounts available for large orders, we strive to provide the best quality Wire Mesh Fence Panels that meet your requirements.

Looking for affordable Perforated Stainless Stee

Explore the factors influencing garrison fencing

Discover the convenience of Temporary Chain Link

Contact: Frank

Phone: 0086-17121115666

Tel: 0086-318-7883678

Email: sales@wiremeshfence.com

Add: 053600 B125-B135 Ziwu Indutries Zone Zi Wen Town Anping County Hengshui Heibei Province China

We chat