Tel: 0086-17121115666

Email: sales@wiremeshfence.com

Steel bar grating is a high-strength, corrosion-resistant solution widely adopted across various industries, including construction, machinery, and railways, among others. Its application is largely due to its versatile properties like high bearing capacity, light structure, anti-corrosive nature, and ease of installation.

Walkways: People use it to make safe paths to walk on in places like parks and factories.

Drain Covers: It covers drains, letting water through but keeping people from falling in.

Stairs: It makes steps less slippery and safer to use.

Platforms: Workers stand on it when they need a stable place to work, especially high up.

Fences: It can serve as a barrier that lets air and light pass through while keeping an area secure.

Shelves: In warehouses, people use it for shelves that hold heavy items because it's strong.

Bridges: Small bridges or footpaths over water or gaps often have flooring made of steel bar grating for safety and durability.

Steel grating, also known as grate flooring, is constructed by welding flat steel and cross/round bars at specified intervals. This method ensures high strength, light structure, and high bearing capabilities. Moreover, it provides convenience during loading, thanks to its unique structure.

Our steel grating offerings at BMP are further enhanced by a hot-dipped zinc coating, offering the product remarkable anti-corrosion properties. This makes our steel grating an excellent choice for projects where exposure to highly corrosive environments is a concern.

We offer a range of specifications to cater to different application needs. For instance, our Bearing Bar (Load Bar) specifications range from 20 x 3 to 100 x 10 for plain and serrated type bars. I-section types are also available in various specifications to cater to different project requirements.

The usage of steel grating extends beyond just flooring. It serves various purposes in different industries, such as platforms, safety barriers, drainage covers, ventilation grates in industrial plants, commercial buildings, and even mezzanine decking.

| Type | Specification | Biggest Size | Cross Bar Width | Bearing Bar Length |

|---|---|---|---|---|

| TMISG001 | G325/30/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG002 | G255/30/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG003 | G323/30/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG004 | G505/30/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG005 | G405/30/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG006 | G355/30/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG007 | G303/40/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG008 | G253/40/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG009 | G385/30/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG0010 | G404/40/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG0011 | G254/40/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

| TMISG0012 | G325/40/100 | 1050MM*6000MM | 175mm-1050mm | 300mm-6000mm |

Steel bar grating's advantages are vast, from being non-slip, anti-corrosion, and hard to deform, to its high safety performance. Its unique structure ensures rain, snow, and dust do not accumulate. Besides, it boasts a simple and beautiful appearance and can easily be installed and removed, extending its lifespan.

Moreover, steel grating can serve various purposes. It is widely used in platforms, stair treads, walkaways, and floors in industrial, civil, and commercial buildings. It offers a high strength-to-weight ratio, shapes without a loss of strength, and allows the passage of heat, light, water, and ice.

At BMP, we comply with various international steel grating standards, ensuring the product's quality and durability. These include China's YB/T4001-1998, USA's ANSI/NAAMM (MBG531-88), UK's BS4592-1987, Australia's AS1657-1985, and Japan's JJS.

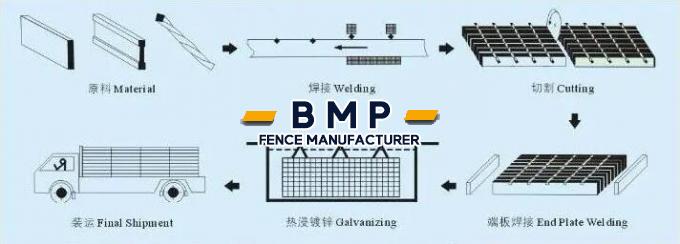

The process of creating steel grating involves a series of steps, from initial design to the final product. The grating is first cut to the desired size before being subjected to welding. The grating is then treated to enhance its durability and longevity.

With their high strength and long service life, steel bar grating products are an indispensable part of various industries. Whether it's construction, mining, or industrial machinery, the strength, convenience, and cost-effective production of steel bar grating make it an essential material.

Durability: It's very strong and lasts a long time, even in tough conditions.

Low Maintenance: Once you put it in place, it doesn't need much care to keep doing its job.

Safety: The surface helps prevent slips and falls, making it safer to walk on.

Easy to Install: It's lightweight and simple to work with, so putting it in place is quick and doesn't require a lot of effort.

Good Drainage: The design lets water, air, and light pass through easily, which is great for drainage and ventilation.

Versatile: You can use it in many different places, like industrial sites, public areas, and commercial buildings.

Cost-Effective: It offers a good balance of price and performance, making it a smart choice for many projects.

At BMP, we ensure our steel bar grating is of the highest quality, offering strength and durability for various industrial applications. With a hot-dipped galvanized finish, our grating provides excellent corrosion resistance that ensures a service life of more than 20 years. Explore our wide range of steel bar grating options today, and discover why we are the trusted name in the industry.

Please note that this is a general overview and word count will vary based on the specific details and requirements provided for each article. Depending on your needs, this could be a starting point for a more comprehensive article.

Looking for affordable Perforated Stainless Stee

Explore the factors influencing garrison fencing

Discover the convenience of Temporary Chain Link

Contact: Frank

Phone: 0086-17121115666

Tel: 0086-318-7883678

Email: sales@wiremeshfence.com

Add: 053600 B125-B135 Ziwu Indutries Zone Zi Wen Town Anping County Hengshui Heibei Province China

We chat